Measuring distributor advance and setting the ignition

timing

with a stroboscopic timing light on Citroën D models

One of the basic, yet most important

steps in a

proper tuneup on any car is setting the ignition timing. On a Citroën

D,

this is no simple task. Most of us have avoided the problem by

resorting to

time-tested methods based on guess-and-by-golly, or perhaps on more

refined,

yet not exacting methods such as turning the distributor to obtain

maximum

power, yet avoid ping or "pink", as Europeans have tended to say.

A great deal of time and effort has been

expended

on this vague aspect of maintaining our cars. This need not be. The

fact that

our cars went through most of their design life with no timing marks is

absurd,

but that does not deter us from loving them. In fact, it adds to their

uniqueness and it should also add to the satisfaction of answering the

challenge of getting our cars running tip-top. Even those of us with

cars that

came with timing marks may be daunted by the timing procedure. I have

decided

to make an attempt to de-mystify this vital step in getting all of the

power

and reliability we can from our cars. To perform a basic tuneup you

will need:

- a fresh breaker point set

and condenser

- cleaned, restored

distributor, ideally, with advance mechanism matched, unchanged and

unaltered

- a tube of point grease,

or high temperature thick grease

- a test light of the same

voltage as the electrical system of your car.

- a copy of #814 or #583

Characteristics, Adjustments and Checks manual (C&A) Download

here.

- A copy of the updated timing chart. The original found in

814 and 583 does not include U.S. specification. Most of them are here.

Let's start with the basics. We will

assume that

the car we are discussing has been unaltered and that it has all of its

original parts. Every engine that comes off the assembly line has a

carburetor

and a distributor matched to give optimum performance. Ignition timing

is

controlled by interaction of the distributor and the rest of the

engine, while

the carburetor must deliver the right ratio of fuel and air in every

condition.

The first step in any tuneup is to install a fresh set of points and a

healthy

new condenser. The new point set should have a dab of high temperature

grease

applied to its bumper so it does not wear excessively as it rubs

against the

distributor cam. Old grease should be removed from the cam, and the

distributor

should be in good condition. The point gap must be set to

specifications.

While a dwell meter can be used, it is more important that the gap be

wide

enough so that, as cam bumper wear inevitably occurs, it does not make

the gap

close prematurely. This is why I simply set them to the maximum

allowable

opening. This, along with proper cleaning and lubrication of the point

bumper/cam, ensures a long lasting tuneup.

If you own a Citroën D, you should by

now be

fully aware of the lack of technical support in places such as the

United

States. It therefore behooves us to be armed with all of the necessary

tools to

maintain your own cars. Despite the seeming complexity of the D, for

the most

part, they are not that difficult to work on and they are famously

robust (except

for rust). One of the most important tools to have is a complete set of

manuals. The other indispensible tool is the Citroen D email

list at CitroenDSID.

Subscription is free and really risk free. There you will be able to

get in

contact with people who can solve most any problem you may encounter.

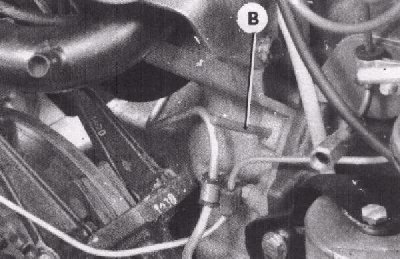

Once the distributor has been properly

serviced,

it must be installed in the car and set to static time. Because D's

have no

external timing marks, except for the latest ones, the flywheel must be

locked

into position and the distributor set using a test light. A specially

made pin

(B) or a 6 mm drill bit is inserted into a hole in the flywheel

housing,

hidden under the alternator. It is a rite of passage for D owners to

discover

that diabolically hidden timing hole. Once you find it, you will swear

that you

can now find the Holy Grail! The first time is the hardest time to find

this

hole. You may have to remove the left front fender to be able to see

it. Later,

you might get away with a strategically placed light and a mirror. This

alone

is reason enough to switch to using a timing light!

The flywheel must be rotated until the

pin drops

into a slot in the flywheel, locking the crank at a specific point,

then set

the distributor can be rotated until the points just open. Touch the

tip of a

test light between coil (-) and a good ground. If the ignition switch

is turned

on, the light should glow when the points are opened. This is where

many of us

stop, and the car will run, but not as well as it should. The

C&A

manual clearly states that the timing should then be set with a strobe

light to

complete the job. Whenever you use this pin, make absolutely

certain that

you remove it before you start the engine or try moving it in any way.

The pin

will break off and the end will stay in the slot of the flywheel,

damaging your

engine!

Most any other car has a ready means of

setting

the ignition timing using a strobe light. Here is where it gets tricky

for a D

owner. Our cars have no access to a component that spins at crank

speed. The

flywheel is buried, and there is no drive pulley off the timing chain

end of

the engine, which is pointing rearward. However, there is an accessory

drive

pulley that runs off the camshaft, which spins at exactly half the

speed of the

crank, and that is what we will use. But timing specifications are

almost

always stated in crank degrees, so setting time from the position of

this

pulley will require this factor to be taken into account. 20 degrees of

crank movement

will produce 10 degrees of camshaft/drive pulley movement.

To add to the confusion, for U.S. spec

cars, the

static timing point is 0 (TDC) starting in November, 1967. Cars built

for the

European market have the static timing point on the flywheel set to 12°

before top dead center (BTDC). In July, 1971 European cars caught up to

U.S.

spec emission requirement and they too changed their flywheels to TDC.

On fuel

injected engines built after July, 1971, the offset is 8 degrees, 30

minutes

BTDC. These factors must be accounted for when calculating the strobe

timing

point. As you will see, you cannot just subtract 12 and get the right

timing

point.

Compensating for the advance curve of

the

distributor piles on even more confusion. As I stated earlier, every

engine has

been matched at the factory with its own distributor. A quick look at

the

advance curves shown in the C&A manual will show that the advance

curve on

many of our cars begins very soon after 0 rpm and moves upwards at

varying

rates and ends at varying speeds. This is controlled by the advance

mechanism

located under the points plate in your distributor, which is rotated to

effect

timing during various driving conditions. The mass and shape of the

weights,

the strength of the springs and the location of the stops determine the

advance

curve for each distributor and are specific to engine type and year.

Because

the timing begins to change as soon as the engine begins to run, if you

simply

set the time at idle speed, you will get an inaccurate reading. This is

why we

must determine the maximum advance speed and set our time while the

engine is

running above that point using the advance curve specifications

specific to our

cars. To proceed, we will need some tools. We will need

- A timing strobe light. It

need not have advance compensation. Lights that are not powered by the

battery are notoriously dim, and are therefore hard to see even in low

light, and should not be used. It is simply unsafe to use them.

One can easily get them and your fingers tangled up with the fan.

Ouch!

- A timing scale, either a

factory made tool, 3078-T or you can make one yourself, using this

drawing as a guide. Click here to view.

Right click and use "save target as" to download it.

- A copy of the

C&A manual, turned to op. 210-0 "Checking and Adjusting Timing".

- Download

a copy of the timing specs for most D's here

Here is the one I

made. All of the

parts came from the local hardware store. The tool is made from a "T"

bracket and a narrow piece of aluminum flat stock. The base leg is bent

up

90° while the ends of the other 2 are shortened slightly and curved to

follow the radius of the pulley. The bar is cut to required length and

has 2

bends in it to allow clearance and proper offset. First the bracket is

attached, then tilted to the correct angle. Then this assembly is held

against

the alternator tensioner and marked from behind for drill hole so

the

face of the timing tool is just away from the pulley. A screw goes

through the

front of this hole, through the slot in the alternator tensioner brace,

then an

oversized nut for spacer, a washer, then a nut to secure all. When

satisfied

with fit, tape and/or glue a timing plate made from paper. Marks are

1/8"

apart. Each increment equals 2 deg. The tool must not rub or interfere

with the

various moving parts, yet hold the scale close to the edge of the

accessory

pulley.

The flywheel is then locked into static

time

position using the hole in the flywheel housing and the pin. Whenever

you

use this pin, make absolutely certain that you remove it before you

start the

engine or try moving it in any way. The pin will break off and the end

will

stay in the slot of the flywheel, damaging your engine! Use a sharp

punch

to make a clear mark on the edge of the pulley adjacent to the "0"

point on the scale, or just use a dab of bright paint. Remember that

this does

not necessarily represent TDC. It is merely a reference point, unless

your

engine happens to have TDC static time.

Now we can apply some basic mathematics

to this

situation. Remember that the distributor runs off the cam and is also

turning

at half the crank speed, therefore distributor time is the same as cam

time.

For the sake of demonstration, lets pick out one of the advance curve

charts

located in the 814 manual. We will work on a 1967 DX European spec.

engine. The

correct chart for this engine C-6, which appears to top out at 9

degrees

distributor time at 2500 RPM. To obtain crank time, we double this

number. Then

the static timing point must be subtracted to negate the offset caused

by the

static timing point. The resulting number must again be divided by 2 to

convert

back to cam time. So:

if D = maximum

advance in

distributor degrees (same as cam degrees) and

S = static timing offset, then

2D - S / 2 = T

T being the reading at a scale mounted on the accessory drive

pulley.

If D = 9 and

S = 12 , then

2 x 9 - 12 / 2 = 12.

With this, you simply set the distributor rotation to 3° on the scale

at

3000 r.p.m.

This chart can be used as a guide to set

time on

any D engine, even the dual point 3 bearing engines found in Traction

Avants

and early D's. Click Here. This

chart, along

with the timing advance graphs located in the C&A manual, may help

you to

find the correct distributor for your engine, should you find that

yours is

incorrect or damaged beyond repair. Fortunately, there is not a really

large

number of possibilities, and the distributor numbers are also located

there to

help you in your search. Remember that the correct advance curve

matched to

your engine along with accurate timing will give you optimal

performance and

efficiency at all speeds.

For owners of U.S. spec cars, the job is

just a

bit more of a challenge. For cars built before 11/67, the Euro timing

curves

should be OK for U.S. cars and therefore, you can use the Euro

procedure. Until

November of 1967, the static timing offset is the same as European

cars, when

they begin using a flywheel with TDC timing set point. I have Service

Bulletin

L-160, which has a curve for the 1967 U.S. spec. DV motor. The curve is

identical to the one found at chart C8, as found in op. 210-0 in the

C&A book.

This formula also works with European cars built after July, 1971,

except fuel

injected cars built after July, 1971, which retain an offset, S=

8°30'. Since U.S. spec cars after 11/67 have their timing holes at TDC,

the

static point correction need not be done. But the formula still holds.

2D - S / 2 = T, with S=0 so

2D/2 = T or just

D = T

It may seem therefore, that a timing

light is not

necessary, but to get repeatable, accurate timing and to avoid the

necessity of

using a flywheel locking pin and test light, this is still far more

practical.

Even though we lack our advance curve charts, all is not lost; we

simply will

need to go one step further. We must discover our maximum r.p.m.'s and

your

maximum advance. The following procedure will reveal this. You will

need to

have your scale mounted, your zero point marked on the accessory pulley

using

the flywheel pin and test light. Attach a tachometer and a timing

strobe light

to your engine. Start the engine and point your light at the pulley and

scale. Make

certain that you have not left the flywheel locking pin in, if you

first set

your static timing point. Begin to rev the engine slowly upward.

You should

not have to go beyond 3000 r.p.m. As the speed increases, you should

see the timing

mark begin the climb up the scale. Write down the maximum degrees and

note your

r.p.m.'s at that point. This is your maximum advance. From now on, you

can set

your time to this point using just your timing light. If you are not

sure that

the distributor is correct for your engine, this procedure can also be

used to

construct your own advance chart. Simply note advance at several

r.p.m.'s and

lay out your results on a chart like the ones in the manual. You can

then

easily compare yours to the book's.

Using a timing light is not only

practical, but it

is a foolproof way to reset our engines to proper time on a consistent

basis

during tuneups and other types of engine work. Even if you find that

regional

differences in fuel quality, altitude, variations in the condition of

our

engines, distributor mismatch or any other factor still cause our

engines to

ping, we can at least have a known starting point for our adjustments.

While I am pretty sure that I have this

all

reasoned out pretty thoroughly, and I have written it in a way that I

hope you

will be able to understand, I am open to suggestions. If you find

discrepancies

or if you can offer some constructive criticism, please email me.

updated 03/12/2024, Copyright 2024, Mark

L.

Bardenwerper, Sr.

Many thanks to Rick Levy and Joe Conte for their technical help and

their keen

eyes!